Slip-In Pump Stations

Product Overview

Barski Industries’ Slip-In FRP Pump Stations provide the most efficient and cost-effective solution for replacing deteriorated or failing concrete / steel pump stations without full excavation or reconstruction. These stations are designed to be installed directly inside existing structures, extending the life of aging infrastructure while providing the corrosion resistance, durability, and reliability of fiberglass.

Each slip-in station integrates Xylem / Flygt submersible pumps for proven performance and reduced maintenance. This combination of FRP construction and Flygt technology enables municipalities and

industrial sites to restore pump station functionality at a fraction of the time and cost of full replacement.

Why Choose Slip-In Over Full Replacement?

Minimal Downtime

Installation time is a fraction of that required for a new build.

Lower Installation Costs

Reuse of Existing Infrastructure

Corrosion Resistance & Longevity

Leach-Free Performance

Concrete stations commonly suffer from leach and groundwater infiltration. Fully sealed FRP construction eliminates groundwater infiltration and exfiltration.

Custom Fit

Key Features

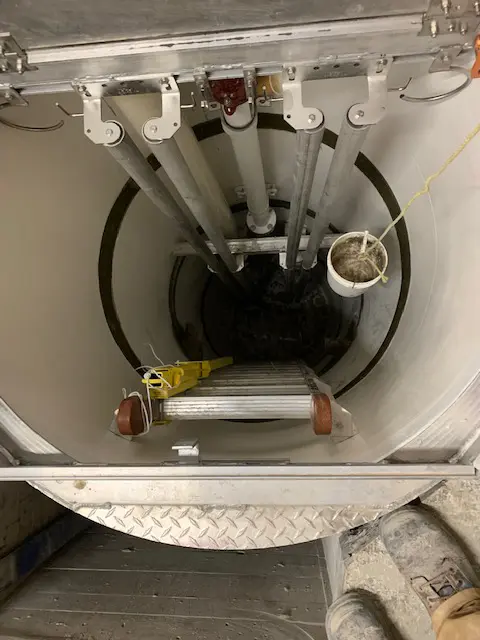

Pre-Assembled for Rapid Deployment

Delivered as a complete unit; only pumps and electrical components are installed on-site.

FRP Construction

Custom Fit for Existing Infrastructure

Confined Space Reduction

Seamless Force Main Connection

Anchoring & Anti-Floatation

H-20 Load Rating Available

25-Yr Warranty

Applications

Municipal Sewer & Stormwater Systems

Industrial & Commercial Facilities

High Water Table Areas

Remote or Difficult Installations

Case Studies & Proven Performance

- Restored service life of deteriorating concrete wet wells

- Eliminated costly groundwater infiltration

- Reduced installation time and avoided extensive dewatering

- Seamlessly integrated with existing mains and piping

Stoney Mountain Replacement LS

Barski Custom FRP Lift Station - Slip-In

Stoney Mountain

Stoney Mountain, Manitoba

6.5’ x 26.5’

Stoney Mountain Replacement LS

136 Ave & Foreman Dr. LS

Barski Custom FRP Lift Station - Slip-In

City of Maple Ridge

British Columbia

9'3 x 32'

136 Ave & Foreman Dr. LS

SaskPower Pit Replacement LS

Barski Custom FRP Lift Station - Slip-In

SaskPower

Saskatchewan

4’ x 14’10

SaskPower Pit Replacement LS

Technical Specifications

Construction & Structure

- Filament-wound FRP with smooth, high-luminous white interior gelcoat

- UV-resistant polyurethane exterior

- Design life: 100+ years

Slip-In Design

- Custom-built to match existing structure dimensions

- Minimal excavation required for lowering into place

Structural Load Capacity

- Designed for full hydrostatic head when empty

- Optional H-20 traffic-rated tops

Nozzles & Piping

- FRP nozzles with laminated or machined ends

- FRP discharge piping rated to 150 PSI (25-year warranty)

- Optional 316 stainless steel piping (5-year warranty)

Anchoring & Anti-Floatation

- Integrated reinforced ribs

- Locked in place with a secondary concrete pour between the old station and new station with only 3” of volume lost

Pumps & Controls

- Compatible with Flygt submersible pumps

- SCADA-ready remote monitoring integration

Access & Safety Options

- Above-ground valve chambers

- Intermediate FRP platforms with removable hatches

- Explosion-proof or intrinsically safe lighting

- Non-slip surfaces, handrails, and fall protection

Warranty

- 25-year warranty on all FRP components (same as a new build)

Frequently asked questions

Have questions? We’re here to help.

What is a “slip-in” station, and when is it used?

A slip-in station is a prefabricated FRP station designed to fit inside an existing failing concrete or steel wet well. Instead of demolishing or replacing the structure, the FRP station is lowered in place. It is designed as an engineered station fully capable of standing on its own.

- Benefits: Minimal excavation, reduced bypass pumping, and extended service life of the existing well.

- Common Uses: Rehabilitation projects, high groundwater sites, or locations where excavation is restricted or cost-prohibitive.

How are Barski FRP slip-in stations installed on-site?

High level installation steps are as follows. Contact us for our full installation procedures.

- Confirm inlet/outlet orientation, elevations, and IDs with Barski.

- Remove all internal components from the existing wet well.

- Expose only the force main and electrical connections.

- Receive the new FRP slip-in station; lower, orient, and level it.

- Fill the station with water per Barski installation drawings.

- Place concrete slurry between the old and new structures up to the lowest inlet.

- Remove water before Barski’s field technician arrives.

- Barski technician completes on-site fit-up (approximately 1 day).

- Backfill with concrete in 4″-6″ increments up to the force main invert.

- Install pumps and commission the station.

How quickly can an FRP slip-in station be installed?

What maintenance needs do Barski FRP stations have?

Are FRP stations more expensive than concrete?

Initial material cost for FRP can be higher than concrete. However, total installed cost and life-cycle cost are often lower due to:

- Faster installation (less labor) and reduced bypass pumping

- All parts and components are fully included in the station price

- Leak-free construction with minimal infiltration

- Long service life with lower maintenance requirements

Why Choose Barski?

Barski Slip-In Pump Stations are the fastest, most cost-effective way to restore failing concrete and steel pump infrastructure without full reconstruction. By extending the life of existing wells while eliminating infiltration,

minimizing downtime, and lowering installation costs, Barski offers municipalities and industries a proven retrofit solution backed by thousands of installations across North America.