TOP Pump Station

Product Overview

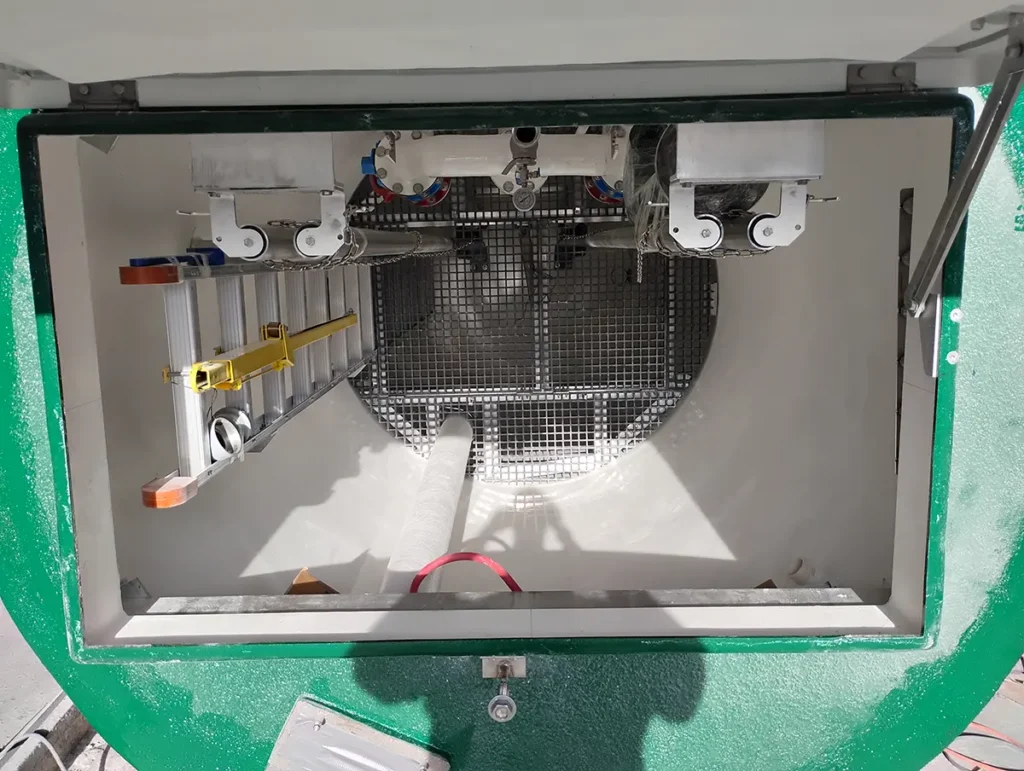

The Barski TOP Pump Station is a pre-engineered, factory-built FRP (Fiberglass Reinforced Plastic) pump station designed to reduce maintenance and extend service life. Developed in collaboration with Xylem/Flygt, the TOP system features a patented sump geometry that keeps solids suspended and directed to the pumps, minimizing buildup and cleaning requirements.

Key Features

Self-Cleaning Sump Design

Xylem Flygt Integration

Durable FRP Construction

Anti-Flotation Stability

Safety Access

Compact Installation

Applications

Municipal wastewater and stormwater management

Commercial and industrial sewage systems

High groundwater sites requiring anti-buoyancy design

Remote or high-maintenance areas where reduced service is critical

Technical Specifications

Tank & Structure

- Filament-wound FRP with smooth white interior liner

- UV-resistant polyurethane exterior coating

- Design life: 50+ years

- Diameter: 4’, 5’, or 6’

- Depth: up to 30’

- Integrated anti-flotation ring

Hydraulics & Piping

- Self-cleaning TOP sump base (4’–6’ diameter range per Flygt design)

- Discharge piping: FRP (150 PSI rating, 25-year warranty) or optional 316 stainless steel (5-year warranty)

- Nozzles: Laminated FRP with machined ends

Pump & Guide Rail System

- Compatible with Flygt submersible pumps

- Pump configurations: simplex or duplex

- Guide rails: 316 stainless steel

Access & Safety

- Safe-Hatch aluminum cover

- Fall protection options

- Non-slip surfaces

- Explosion-proof or intrinsically safe lighting available

Monitoring & Controls

- SCADA-ready controls

Ventilation

- FRP or stainless steel goosenecks and venting systems

Warranty

- 5-year warranty on all FRP components

Proven Performance Backed by Case Studies

Creekside Valve Vault

TOP Lift Station

City of Grand Prairie

Texas

5' x 7'

Creekside Valve Vault

Creekside Wet Well

TOP Lift Station

City of Grand Prairie

Texas

6' x 28.5'

Creekside Wet Well

Port Picton Subdivision

TOP Lift Station

Port Picton

Ontario

5' x 21'

Port Picton Subdivision

Lacebark Lane

TOP Station

Medford

New York

6' x 25'

Lacebark Lane

Why Choose the TOP Pump Station?

- Reduced Maintenance: Self-cleaning sump eliminates the need for manual cleaning, reducing service calls and downtime.

- Long-Term Reliability: FRP construction resists corrosion and deterioration, outperforming concrete stations

- Faster Installation: Delivered as a complete, factory-built system for rapid installation and lower site costs

- Eco-Friendly & Cost-Effective: Energy-efficient Flygt pumps reduce operating costs and environmental impact.

Frequently asked questions

Have questions? We’re here to help.

What are “TOP Stations”?

TOP (Total Optimal Performance) Stations are standardized FRP wet wells developed in collaboration with Xylem / Flygt

- Sizes: Available in 4 ft, 5 ft, and 6 ft diameters (depths up to ~30 ft).

- Design: Hydraulic benching and flow channels are built into the sump to improve solids handling and reduce maintenance.

- Use Cases: Smaller municipal lift stations, subdivision pumping, and projects requiring shorter lead times.

- Advantages: Proven hydraulic performance, reduced maintenance, and faster delivery compared to fully custom stations

How quickly can an FRP station be installed?

Installation is typically much faster than cast-in-place concrete. Once the base slab has cured, the FRP station can be lowered and tied in within a single workday. This reduces bypass pumping costs and overall construction time.

What piping materials are available?

Barski supplies discharge piping in multiple materials depending on specification and service conditions:

- 316 Stainless Steel: Often required by municipal specifications.

- PVC: Often required by municipal specifications.

- FRP (Fiberglass Reinforced Plastic): Corrosion-resistant, lightweight, rated for 150 PSI.

Are FRP stations more expensive than concrete?

Initial material cost for FRP can be higher than concrete. However, total installed cost and life-cycle cost are often lower due to:

- Faster installation (less labor) and reduced bypass pumping

- All parts and components are fully included in the station price

- Leak-free construction with minimal infiltration

- Long service life with lower maintenance requirements

Do you provide budgetary quotes or preliminary estimates?

Yes. With basic project data (flows, station size, diameter, piping details), Barski can provide a budgetary estimate. A detailed, final quotation requires complete design parameters.

Why Choose Barski?

Barski Slip-In Pump Stations are the fastest, most cost-effective way to restore failing pump infrastructure without the need for full reconstruction. As a trusted partner of Xylem Flygt, we ensure that each station is equipped with the best-in-class pumping technology, optimizing performance while lowering operational and maintenance costs.

Our slip-in technology saves municipalities and industrial sites millions by eliminating the need for full excavation, new infrastructure, and prolonged downtime. With over 5,000 installations worldwide, Barski is the leader in high-performance FRP pump stations.